As the core component connecting the door and the door frame, the hinge plays a vital role in the use of the door. Although traditional hinges are widely used, they usually face the common problem of “door collision”, especially the sudden impact when the door is closed, which will cause damage to the door frame, door panel, and even the hinge itself.

Fortunately, with the emergence of hydraulic buffer technology, the function of hinges has been revolutionized. And door collision can also be avoided as much as possible. As a professional furniture hinge manufacturer, we will introduce hydraulic buffer technology in detail to help you understand the mechanical structure of hinges and explain why this technology can reduce door panel collision by up to 70%.

What Is Hydraulic Buffer Technology?

Hydraulic buffer technology uses the physical principle of liquid flow to control the closing speed of the door through the hydraulic system to alleviate the inertial impact of the door when closing. The hydraulic hinge adjusts the fluid pressure during the door closing process through components such as built-in hydraulic pistons, sealing devices, and liquid cavities, so that the door can slow down when it is close to closing, avoiding violent collisions between the door panel and the door frame. Specifically, when the door closes quickly, the liquid flows into the piston cavity and gradually slows down the movement of the door, thereby achieving a buffering effect.

| Components | Function |

| Piston | Controls the flow of liquid, slows down the movement of the door, and avoids the impact force caused by rapid closing. |

| Liquid chamber | The area where liquid is stored and compressed is responsible for regulating the speed and pressure during the door closing process. |

| Sealing device | Ensure that the fluid does not leak in the system and maintain the efficient operation of the hydraulic system. |

The hydraulic buffer hinge uses the coordinated action of these components to gradually slow down the door when closing, reducing the impact of the door panel.

Mechanical Principles of Hinges

Traditional hinges rely mainly on the friction of metal parts to control the opening and closing of doors, but this method often results in violent impact when the door is closed. When the door is too fast, too heavy, or lacks an effective buffer device, a large impact force will be generated when the door is closed, which will put pressure on the door frame, door panel and hinges. This impact will not only damage the surface of the door, but also cause the door frame to loosen and even affect the normal use of the hinge.

Compared with traditional hinges, hydraulic hinges prevent the door from hitting the door frame at high speed by precisely controlling the door’s movement speed. The hydraulic system’s function is to smoothly guide the door to slow down during the closing process, so that the door closes in a more gentle manner.

Why does the door panel hit the frame?

Door impact problems are mainly caused by fast closing and high inertia.

When the door closes fast, the door panel usually contacts the door frame at a high speed due to the mass and inertia of the door. Without a buffer, the impact force of the door will be very large.

The inertia of the door during the closing process makes the door take longer to stop. Without an effective deceleration mechanism, the door will continue to accelerate until it hits the door frame.

These factors lead to the problem of door panel collision. The collision will not only damage the door frame and door panel, but also may produce strong noise, affecting the living or working environment.

How Does Hydraulic Buffering Reduce Door Panel Impact?

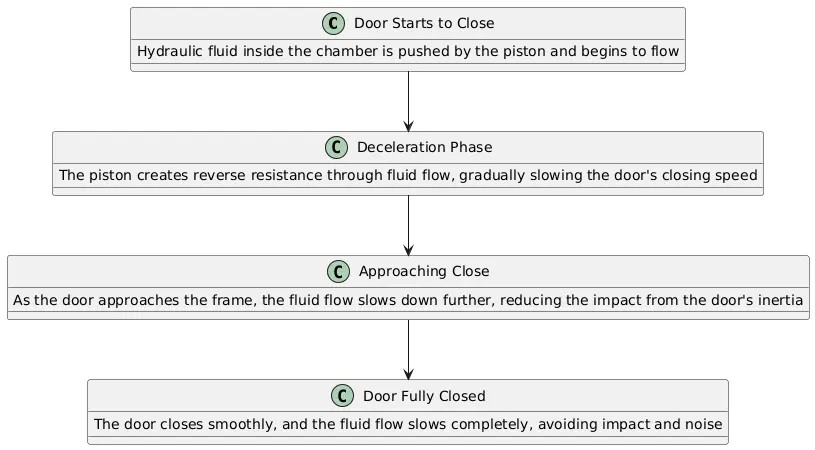

When the door starts to close, the liquid in the liquid chamber begins to flow, creating a buffering effect. Next comes the deceleration phase, where the door closing speed gradually slows down, and the hydraulic system provides reverse resistance to slow down inertia. When the door is close to being fully closed, the liquid flow further slows down the door speed to reduce impact. Then, the door closes at a steady speed, achieving full closure, avoiding impact force, and keeping the door frame and door panel intact. This buffering effect can significantly reduce the impact force of the door and avoid the strong collision between the door panel and the door frame in traditional hinges.

Here is a graph below to help you understand it more clearly:

Advantages of hydraulic buffer technology

Hydraulic buffer technology can not only reduce the frequency and intensity of door panel impact, but also has many other advantages:

- Reduce impact and wear: Hydraulic buffer can reduce the violent impact between the door and the door frame, reduce the wear of the door, and thus extend the service life of the door.

- Extend the service life of the door: Since the impact force when the door is closed is small, the loss of the door frame, door panel and hinge is reduced, and the durability of the door is improved.

- Reduce noise: The smooth closing of the door greatly reduces the noise of the door closing, making the living or working environment more quiet and comfortable.

- Improve safety: Hydraulic buffer technology avoids the situation where the door is suddenly closed with force when closing, reducing the risk of the door hitting people or objects, especially for families with children or the elderly, increasing safety.

Practical application of hydraulic hinges

Hydraulic hinges are widely used in various types of doors and building structures, especially in places with a high frequency of use and requiring quiet and safe closing. The effect is particularly significant.

| Application Area | Effects and Benefits |

| Home Doors and Windows | Provides quiet and safe door closures, ideal for homes with children or elderly people. |

| Commercial Building Doors | Significantly reduces wear on doors with frequent use, extending the lifespan of the building. |

| Industrial Doors | Hydraulic hinges reduce the impact of closing heavy doors, making them suitable for complex industrial environments. |

| Car Doors | Used in car doors and other automotive components, reducing impact noise during closure. |

In these locations, hydraulic buffer hinges can provide a smoother and safer door closing experience, extend the service life of doors and hinges, reduce noise, and improve the overall user experience.

Conclusion

Hydraulic buffer technology provides significant improvements to the design and function of traditional hinges, making the use of doors smoother, safer and quieter. By reducing the impact force, hydraulic hinges can effectively extend the service life of doors, reduce repair and replacement costs, and improve the comfort and safety of living environments. Hydraulic buffer hinges are not only suitable for home and commercial use, but are also widely used in industrial and automotive fields, playing an irreplaceable role.

If you are looking for an efficient, safe, and long-lasting hinge solution, hydraulic buffer technology is undoubtedly an ideal choice. We are a professional hinge manufacturer and wholesaler, and we support customers with different degrees of customization. Buy our products and upgrade your door hinges to make your doors more durable, safe, and quiet.