Commonly, there is a cognitive trap: low price equals cost-effectiveness, in hinge procurement. On one hand, low price hinges seemly save explicit cost, but implicit costs like after-sales maintenance, loss of brand reputation, and repeated replacements are often far greater than expected.B2B buyers (construction companies, industrial manufacturers, and commercial enterprises) and individual buyers (homeowners, small businesses, and DIY enthusiasts) face this dilemma.

As a professional furniture hinge manufacturer, from our perspective, the real “best value” should be the minimum life cycle cost (LCC) under the premise of meeting the needs. In this blog, we will guide you through the decision-making process to ensure you get the best value from your hinge purchase, whether you’re buying in bulk for a commercial project or purchasing a single hinge for your home.

Understand the Influencing Factors of Cost

Types of Materials

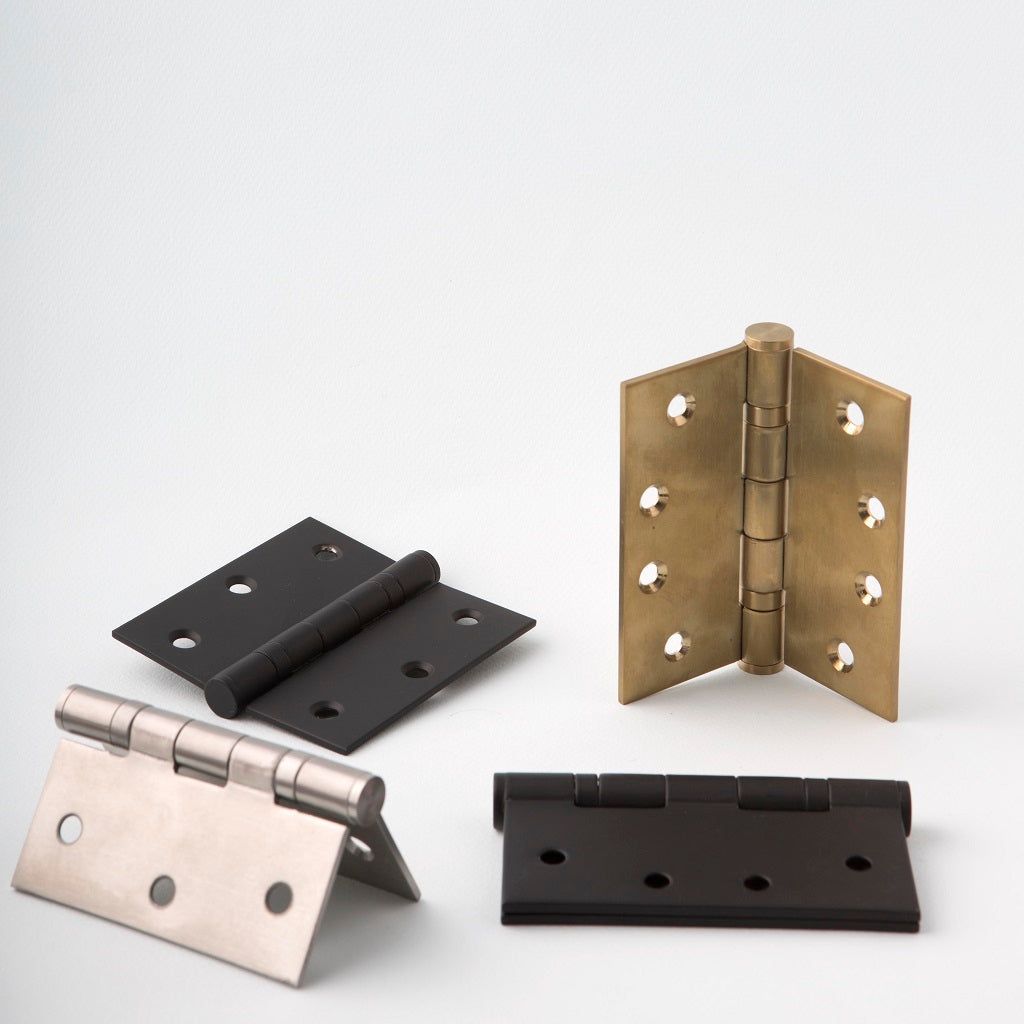

The material of a hinge directly affects its cost, durability, and performance. Common hinge materials include stainless steel, brass, zinc alloy, and aluminum, each of which has its advantages and disadvantages.

- Stainless steel: Stainless steel is known for its strength, rust resistance, and durability, and is often the first choice for high-quality hinges, but it is more expensive.

- Zinc alloy: Zinc-based alloys are more affordable and have good corrosion resistance, but may not be as durable as stainless steel in harsh environments.

- Brass: Brass hinges are often used for decoration and are durable and beautiful, but they are more expensive than standard steel.

- Aluminum: They are lightweight and corrosion-resistant, making them an affordable choice for non-heavy-duty applications.

- Nickel-Plated Iron: Nickel-plated iron combines the strength of iron with the corrosion resistance of nickel. The plating gives it a shiny finish and helps prevent rust, so it’s suitable for areas with moderate humidity. It’s more affordable than stainless steel, but offers similar protection. However, if the plating is scratched, the iron underneath may rust, so it’s not suitable for heavy-duty work or outdoor use.

B2B buyers: For commercial projects, you might need hinges that can withstand heavy use, adapt to various environmental challenges, and meet safety standards. Stainless steel or corrosion-resistant alloys are usually acceptable, even if the cost is higher. Bulk purchasing can also help reduce material costs in the long run.

Nickel-plated iron hinges provide a cost-effective solution for budget-conscious projects. For furniture manufacturers, nickel-plated iron hinges are an ideal choice for low-cost furniture. They are economical and do not sacrifice basic functions, making the market price of furniture more advantageous and targeting low-budget groups to attract budget-conscious consumers.

Individual buyers: If you are working on a small home improvement project, you may not need high-quality stainless steel unless it involves outdoor or exposed areas. For indoor applications, more affordable materials such as zinc alloy or brass shall be sufficient.

Manufacturing Complexity

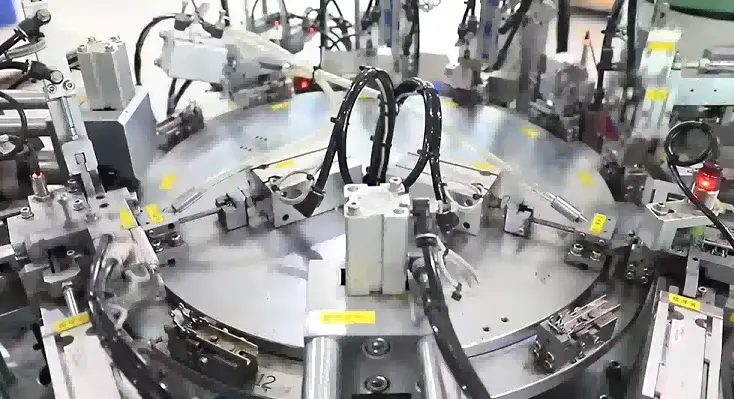

Hinges come in a variety of designs, from simple butt hinges to more complex concealed, continuous, or custom hinges. The complexity of the manufacturing process directly affects the price.

- Mass-produced hinges: These hinges are generally cheaper because they are produced in large quantities, often using automated processes.

- Custom or specialty hinges: Custom hinges designed for specific needs (decorative or non-standard sizes) or functions (self-closing, soft-closing, or heavy-duty) are more expensive.

B2B buyers: It is often more cost-effective to purchase mass-produced, standardized hinges for large commercial projects. In specific high-end or specialized commercial environments (e.g., hospitality, high-security buildings), however, custom hinges may be necessary.

Individual buyers: For homeowners or small businesses, standardized furniture hinges are often sufficient for everyday use. Standardized hinges are easy to install and affordable, making them ideal for common furniture such as cabinets, doors, and wardrobes. Individual buyers can choose hinges that match their style preferences while keeping costs low.

Finishes and Coatings

The finish or coating of a hinge can greatly affect its appearance, corrosion resistance, and price as well. Common finishes include galvanizing, powder coating, and chrome plating, which can enhance the durability and aesthetics of a hinge.

- Galvanizing: A basic finish that is inexpensive and corrosion resistant.

- Powder coating: The method offers stronger corrosion protection and a variety of color options, but is more expensive.

- Chrome or brass plating: Chrome or brass-plated hinges are often used for decoration, adding an extra layer of protection and beauty, but at a higher cost.

Here is a comparison table below:

| Factor | Impact on Price Increase | Reason |

| Materials | ★★★ | High-quality materials (e.g., stainless steel, brass) cost more due to their durability and performance. |

| Manufacturing Process | ★★★ | Complex manufacturing processes, such as customization or precision machining, increase production costs. |

| Finishes and Coatings | ★★ | Special finishes (e.g., powder coating, chrome plating) add to the cost by requiring additional processing and materials. |

B2B Buyers: In industrial or commercial settings, where hinges are exposed to harsh conditions (moisture, chemicals, or frequent use), the extra cost of a quality coating is worth it due to their long life span and low maintenance requirements.

Individual Buyers: For home improvement projects, coatings such as powder coating or chrome plating may be appropriate for exterior doors, gates, or decorative applications. For interior applications, however, where aesthetics are less important, a simpler galvanized finish can save costs.

Benefits of Investing in High-Quality Hinges

Long-Lasting Durability and Superior Performance. High-quality hinges are built to last. They are made with premium materials, precision craftsmanship, and advanced coatings that enhance their resistance to corrosion, wear, and tear. While the upfront cost may be higher, they provide long-term value by lasting longer and requiring fewer replacements.

B2B Buyers: In industries where hinges are used frequently or in demanding environments, such as commercial kitchens, factories, or airports, choosing high-quality hinges can help prevent costly failures. Over time, the performance benefits of a quality hinge, such as easy operation and low maintenance, will outweigh its initial cost.

Individual Buyers: If you are purchasing a security door or a high-traffic entry door, high-quality hinges can provide you a peace of mind and avoid problems later. For instance, corrosion-resistant stainless steel hinges will maintain their performance and appearance for decades.

Hidden Costs of Cheap Hinges: Performance Doesn’t Meet Expectations

Cheap hinges may seem like a good deal at first, but they often don’t perform as well as expected. They can rust, misalign, or even break under stress. These failures can lead to expensive repairs or even safety issues, especially in critical commercial applications.

B2B Buyers: In a commercial setting, choosing cheap hinges for heavily used scenery (fire doors, security doors) can have long-term costs. Failures can cause operational delays, safety hazards, or compliance issues.

- Direct loss: Due to the hinge quality not meeting the standard, related quality problems were caused, the customer complaint rate soared, and free hinge replacement service and free hinges were provided.

- Indirect loss: The after-sales team needs to make on-site repairs, and the cost of a single on-site visit includes expensive labor and transportation costs, and after-sales service is also required for free hinges.

- Brand loss: Customer repurchase rate plummeted, and annual sales decreased significantly.

Individual buyers: When used at home, cheap hinges may break faster than expected and need to be replaced or repaired. Damaged hinges on a high cabinet may even pose a safety hazard.

- Maintenance cost: Frequent cleaning, lubrication, and even professional repairs are required.

- Replacement cost: Early replacement due to damage or insufficient performance, and the accumulated cost of multiple purchases.

- Time and energy: The time cost of handling faults, contacting after-sales, and waiting for installation is the most awful time in life.

- Safety hazard: Insufficient load-bearing causes door panels to fall, which may cause property damage or personal injury.

- Home environment damage: Rust, water leakage, etc., cause damage to surrounding furniture or walls, resulting in additional repair costs.

Evaluating Total Cost of Ownership: Total Lifecycle Cost

The total cost of ownership goes beyond the initial purchase price. When evaluating hinges, consider factors such as installation costs, maintenance costs, and how often they need to be replaced. High-quality hinges may have a higher initial cost, but they require fewer repairs, which can save you money, especially time, in the long run.

B2B Buyers: For commercial projects, the total cost of ownership includes not only the purchase price but also installation, long-term maintenance, and any associated shutdown costs. High-quality hinges may cost more at first, but you can save money by reducing maintenance needs and extending their lifespan.

Individual Buyers: For home use, the upfront cost of high-quality hinges may seem high, but consider that you won’t have to replace them as often, and you’ll save money on repairs in the future. For example, stainless steel exterior door hinges will last much longer than cheaper hinges.

Certification and Quality Assurance

Certifications from recognized bodies (e.g., ISO, UL, CE) ensure that hinges meet specific quality and safety standards. These certifications ensure that hinges have been tested for durability, functionality, and safety.

B2B Buyers: In industrial and commercial applications, choosing certified hinges ensures compliance with building codes, safety standards, and legal requirements. For example, fire-resistant hinges are essential for security doors. Choosing certified products ensures that they meet the necessary fire standards.

Personal Buyers: When purchasing hinges for home use, certified products provide an extra layer of security, especially for high-risk areas such as exterior doors. Certification makes sure that the hinges will last longer and perform better, as well.

How to Find the Balance: Cost vs. Value

The ultimate goal is to find a hinge that strikes the right balance between cost and value. While it’s tempting to choose the cheapest hinge, it’s also critical to consider the hinge’s performance and longevity. For both B2B and individual buyers, the key is to understand your specific needs and find a hinge that will provide the best long-term benefits.

B2B Buyers: For commercial projects, high-quality hinges that meet safety, durability, and performance standards may cost more initially, but they will reduce maintenance issues, regulatory concerns, and customer complaints in the long run.

Individual Buyers: For individual projects, consider how the hinge will be used. If you’re installing a door with a huge foot traffic, investing in a durable, high-quality hinge is a smart option. For cabinet doors that aren’t used often, a budget-friendly option may be sufficient.

Conclusion: The Core of Value is “Need Matching”, not Simply Comparing Prices

Choosing the right hinge is not just about choosing the cheapest or the best quality product; it is about finding the balance that best meets your specific needs, budget, and long-term goals. Whether you are a B2B buyer managing a large commercial project or an individual looking to improve your home environment, it is important to consider factors beyond the initial cost of the hinge and consider the total value it can bring in the long term.

Value has two aspects. They are cost and lifespan. It is about how the hinge performs in the specific environment for which it is designed. In short, needs determine the right product for you. Furthermore, carefully evaluating the material, surface treatment, performance, and lifespan of the hinge shall be on your consideration list. By balancing cost and quality, you can ensure that the hinge operates efficiently and lasts for a long time, providing you with the best value in the short and long term.

As a professional hinge manufacturer, owning industrial-related certificates, we are providing a deep custom solution for you. No matter for a business project or home improvement, we have the right hinge for you.