For many years, furniture hinges have been hidden behind closed doors, but by 2026, hinges will play a greater role in perceiving product quality, sustainability claims, and user experience.

In the following text, Mingrun, a professional hinge manufacturer, will elaborate on the trends that furniture manufacturers, hardware suppliers, designers, and specification makers should pay attention to, and explore their practical significance and immediate actions to be taken.

Hinge Innovation: The Unseen Driver of 2026 Furniture Value

Several market forces have accelerated hinge innovation:

- Growth in custom cabinetry, modular furniture, and micro-living demands hardware that is flexible and compact.

- Consumers expect low-maintenance products with a premium feel; hinge behavior is a tangible part of that perception.

- Sustainability and procurement rules push suppliers toward cleaner finishes and recyclable materials.

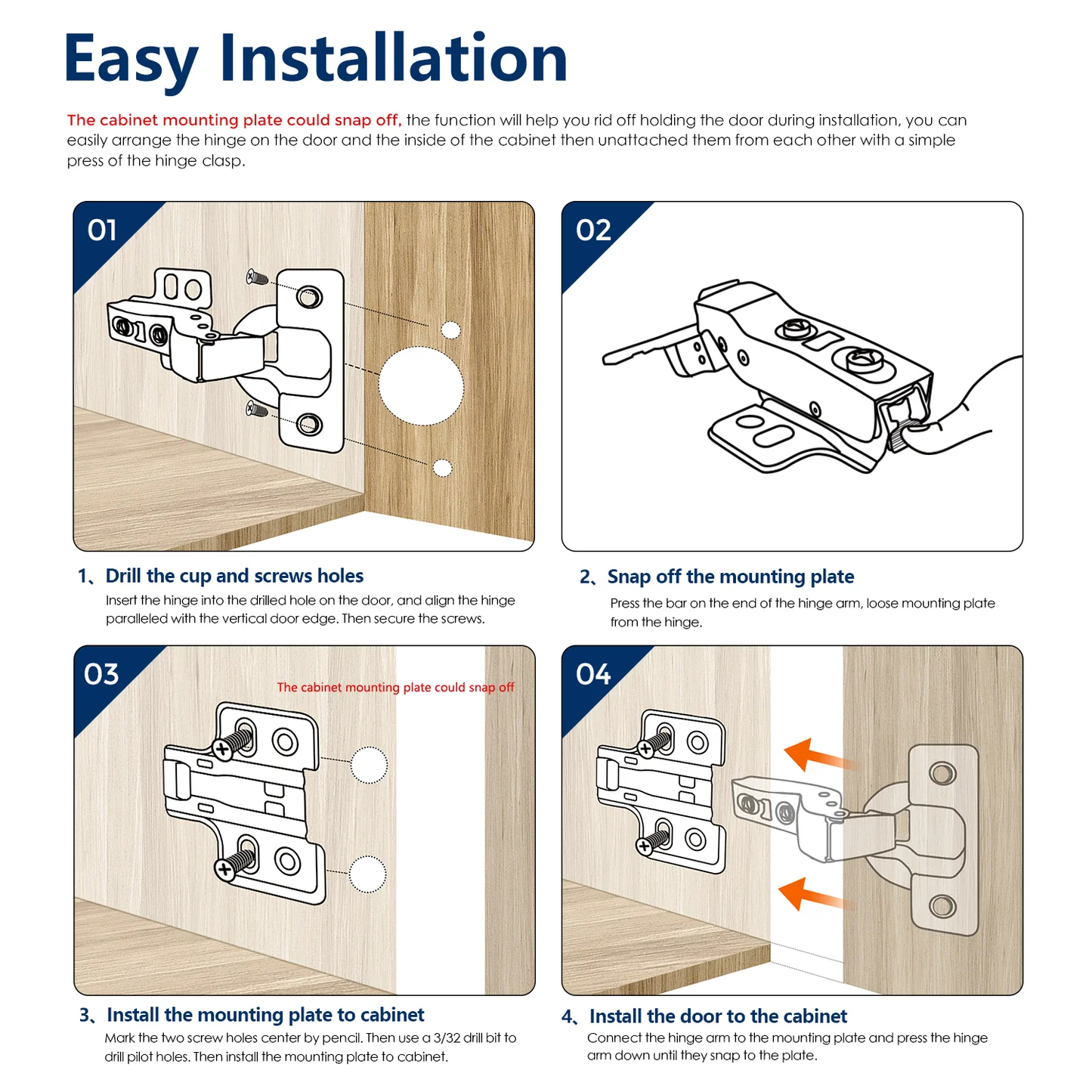

- eCommerce and DTC furniture require easy installation and fewer field-service calls.

All of these factors mean the right furniture hinge contributes to brand value, reduces warranty claims, and supports circular-design strategies.

🔍Soft-close and Refined Damping Are Mainstream

Soft-close has moved from a luxury option to a mainstream expectation.

What’s changed

- Damping units are quieter, smaller, and longer-lived. Better seals, improved damping fluids, and stronger pistons have reduced failure rates.

- Adjustable damping (installer- or user-tunable close speed) is now available in mid-range products.

- More manufacturers publish durability test results, and OEMs report fewer slam-related warranty calls.

Why it matters

Soft-close improves perceived quality and reduces damage to doors and frames. For brands, it lowers after-sales costs and increases customer satisfaction.

Design palettes continue to favor matte blacks, warm metals (bronze/rose), and two-tone schemes that match pulls and faucets.

🔍Corrosion-resistant Materials and Premium Finishes Proliferate

Aesthetic and durability demands are converging.

Trends

- Broader use of stainless steel, PVD (Physical Vapor Deposition), DLC, and ceramic-like finishes — especially for coastal and humid markets.

- Design palettes continue to favor matte blacks, warm metals (bronze/rose), and two-tone schemes that match pulls and faucets.

- Buyers increasingly request objective coating data (salt-spray hours, adhesion classes).

Implications

Specifiers should insist on test evidence; manufacturers must scale surface-treatment capacity and tighten QA to meet orders.

🔍Smart and Sensor-enabled Hinges Move into Early Commercial Use

Smart hinge concepts are shifting from lab pilots to initial deployments.

Emerging features

- Open/close sensors for auto lighting or soft-open triggers, helpful in accessible design.

- Simple wear monitoring that flags increased friction or damping degradation to facility managers.

- Integration trials with kitchen/closet IoT platforms for hands-free interactions.

First adopters

Hospitality, healthcare, and high-end smart homes are leading early use — where added functionality and data justify higher prices.

🔍Modular, Interchangeable Systems Accelerate Customization

Brands want differentiation without heavy tooling investments.

What to expect

- Modular mounting plates and interchangeable arms/dampers let OEMs mix functions without new dies.

- Online configurators help designers choose geometry, finish, and damping for quick quotes.

- Lower-MOQ tooling and 3D-printed prototypes speed product iteration.

Why it matters

Customization at scale: designers get variety, manufacturers keep production efficient.

🔍Factory digitization tightens quality control

Precision and consistency are non-negotiable.

Upgrades

- Automated insertion lines, vision inspection for coating consistency, and digital traceability (batch IDs, coating lot data).

- Automation lowers unit cost, improves tolerances, and reduces lead times.

Outcome

More consistent furniture hinge performance and quicker turnaround for custom runs.

🔍Sustainability & Circularity Become Procurement Requirements

Sustainability is now a purchasing filter, not only marketing in the furniture hinge industry.

Actions in play

- Use of recycled metals, low-VOC powder coatings, and PVD processes with improved environmental profiles.

- Design for disassembly: hinges that make doors removable for repair or recycling.

- Suppliers increasingly publish basic traceability and ESG data.

Competitive edge

Brands that demonstrate lifecycle benefits and recyclability gain access to green tenders and eco-minded buyers.

Risks & Practical Challenges

- Rising costs for specialty alloys and coating chemistries vs. pressure to hold retail prices.

- Supply-chain fragility for niche materials and chemicals.

- Need to balance innovation with existing standards (cup sizes, mounting patterns) to maintain interoperability.

Actionable Recommendations

Manufacturers: Expand surface-treatment capacity (PVD/powder), pilot modular systems, and field-test smart hinges in hospitality.

Buyers/OEMs: Require coating test data, ask for modular specs, and run small pilots for smart features.

Marketers: Lead with durability, low maintenance, and sustainability — these drive conversion.

Conclusion

By 2026, the furniture hinge has shifted from a basic necessity to an aesthetic detail. Quieter operation, superior corrosion resistance, modular customization, emerging smart capabilities, and verified sustainability credentials will tell the winners. Treat hinges as a value lever—invest in quality, testing, and modularity—and you’ll improve product perception, reduce lifecycle costs, and differentiate in a crowded market.

About Mingrun

Mingrun is a professional hinge manufacturer specializing in high-quality furniture hinges built for precision, strength, and long-term durability. Our factory operates with advanced automation and streamlined production systems, enabling large-scale output without compromising quality.

Backed by a reliable supply chain and efficient logistics, we ensure every custom hinge solution is delivered quickly and consistently. Mingrun is the partner you can trust for stable supply, competitive lead times, and dependable service.