Successful cabinet hinge manufacturing requires a combination of meticulous design, careful material selection, precision molds, controllable production processes, and strict quality control. Whether you are a specification maker, procurement manager, or furniture brand, understanding this entire production chain can help you choose the right cabinet hinge manufacturer and evaluate suppliers like real partners – rather than just seeing them as mere suppliers.

As a professional hinge manufacturer, Mingrun will walk through the typical stages used in a modern cabinet hinge factory, explaining what matters at each step and what to ask your supplier.

Product Design & Engineering

Everything begins with product requirements. At the beginning of cabinet hinge manufacturing, Engineers define:

- Functional targets: load rating, opening angle, soft-close or not, cycle life.

- Installation interface: cup diameter, mounting plate pattern, overlay/inset geometry.

- Aesthetic goals: visible surfaces, finish options, and tactile feel.

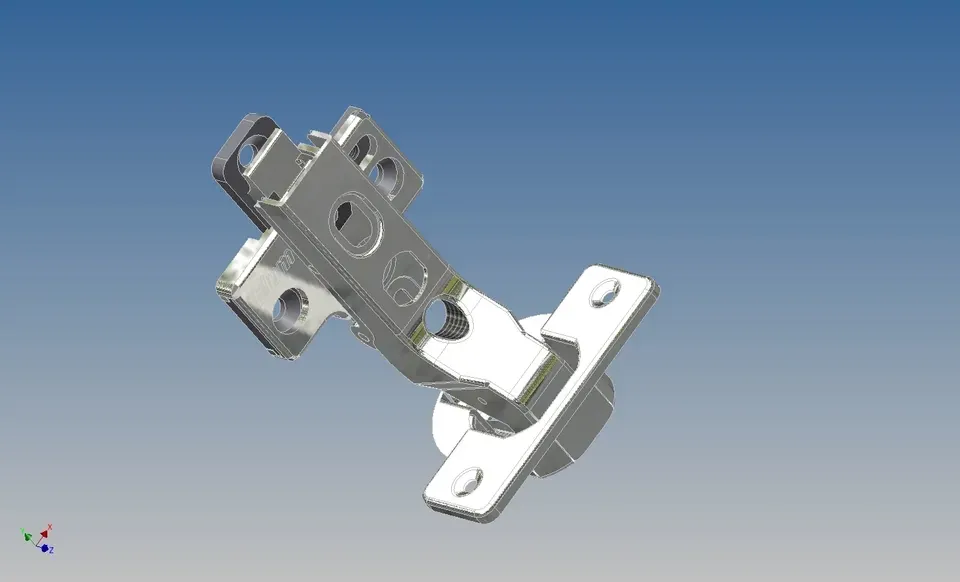

Design teams use 3D CAD and FEA (finite element analysis) to validate stress points and optimize geometry. Rapid prototyping (CNC or 3D printing) creates test samples so the design can be trial-fitted on real doors before tooling is committed.

What to ask: Request CAD drawings and prototype photos. A professional cabinet hinge manufacturer will share design iterations and test reports.

Material Selection

Material choices determine strength, corrosion resistance, and cost:

- Hinge cups & arms: often high-tension cold-roll steel, stainless steel, or zinc die-cast, depending on strength and budget.

- Springs: high-carbon or stainless steel. They must undergo precise heat treatment and the shot peening process to ensure consistent torque output and excellent fatigue life of the spring

- Dampers (soft-close): precision pistons with elastomer seals and damping fluids. The material must withstand temperature changes to ensure that the soft closing speed remains stable in different seasons

- Fasteners/inserts: stainless screws or brass inserts to avoid galvanic corrosion.

A good cabinet hinge factory can explain trade-offs (e.g., zinc is cheaper but needs better coatings; 316 stainless resists coastal corrosion).

Tooling & Mold Making

Tooling quality sets the tolerance baseline. Typical tooling steps in cabinet hinge manufacturing:

- Design and mill die-casting molds or progressive stamping dies.

- Trial runs and mold tweaking (T1–T3) ensure dimensions and surface detail meet specs.

- High-precision tooling reduces scrap and assures consistent performance across runs.

Tooling is expensive but essential — poor dies mean poor hinges, even if the design is good.

Core Cabinet Hinge Manufacturing Processes

Most hinges combine several metalworking methods:

A. Stamping / Pressing

Steel parts like cups, plates, and linkages are stamped, trimmed, and often heat-treated to achieve the necessary hardness and fatigue strength. Progressive dies allow complex shapes to be formed in continuous operations.

B. Die-casting

Zinc alloy components (common for cost-effective hinges) are die-cast, degated, and tumbled. Critical features are CNC-machined afterward for precision fit.

C. Spring Production

Coiling, heat treatment, and shot-peening produce springs with predictable torque and fatigue life.

D. Damper Assembly

Soft-close units require precision valves, seals, and calibrated oil charges. Dampers are tested individually for consistent damping profiles.

E. CNC Finishing

Key features — holes, rabbets, and bearing surfaces — receive CNC machining to meet tight tolerances.

A mature cabinet hinge factory stages these processes to reduce handling and protect sensitive finishes.

Surface Treatment & Finishing

Surface finishing protects and styles hinges. It is the key link between functionality and market value in cabinet hinge manufacturing. Common treatments:

- Electroplating (Ni/Cr) for shiny finishes.

- PVD for durable decorative finishes (black, bronze, etc.).

- Powder coating for robust colored finishes.

- Passivation/electropolish for stainless components.

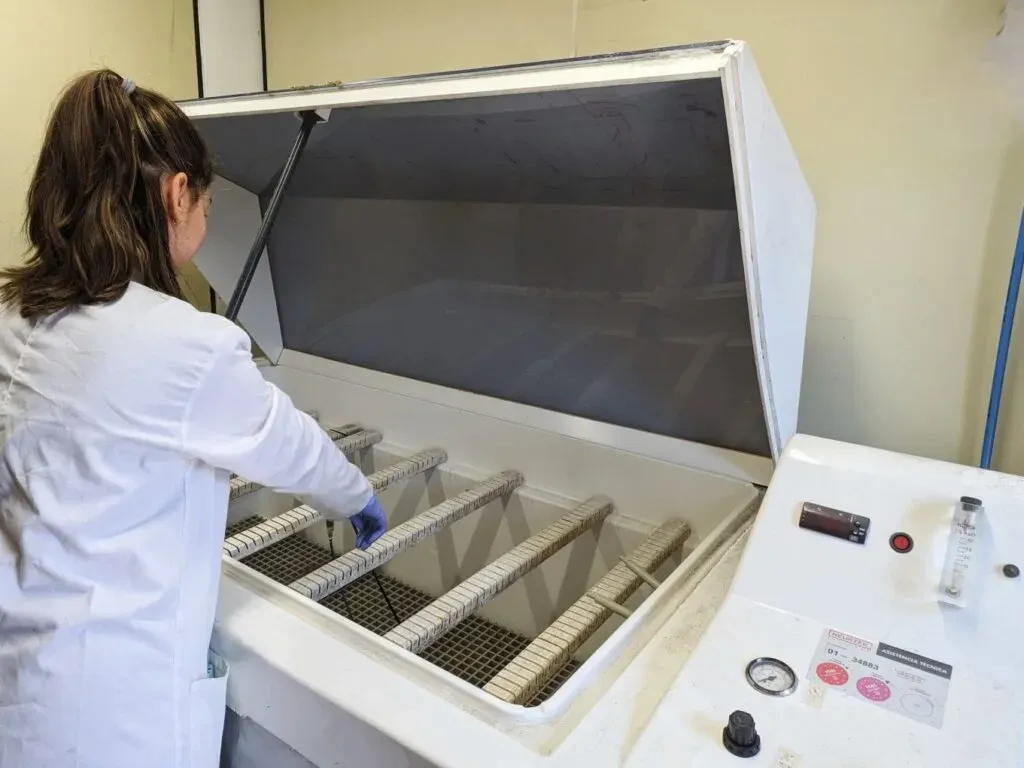

High-quality factories run adhesion tests, salt-spray (ASTM B117), and thickness checks. Don’t accept a finish claim without test data.

Assembly & Automation

Assembly may be manual, semi-automated, or fully automated, depending on volume:

- Sub-assemblies (spring blocks, dampers) are produced and tested.

- Final assembly lines mount springs, dampers, and plates, then set torques.

- Clip-on mechanisms are fitted and checked for engagement strength.

Automation improves consistency; however, precision manual assembly still matters for premium lines.

Quality Control & Testing

Quality control is non-negotiable in reputable cabinet hinge manufacturing:

- Dimensional inspection (calipers, CMM).

- Cycle testing: open/close cycles to validate life (typical 50k–200k cycles depending on spec).

- Damping consistency tests for soft-close units.

- Corrosion testing: salt-spray reports for plated/coated parts.

- Visual & finish inspection for blemishes or plating flake.

Ask prospective suppliers for QC certificates and representative test logs. A reliable cabinet hinge manufacturer will provide these without prodding.

Packaging, Traceability & Logistics

Good packaging protects finishes in transit: sealed bags, desiccants, and cushioned cartons reduce moisture and abrasion risk. Traceability (batch codes, coating lot IDs) helps manage recalls and warranty claims.

For exporters, factory capabilities to manage palletizing, export documentation, and transit-safe packing are critical.

Choosing the Right Supplier

When evaluating a cabinet hinge factory or cabinet hinge manufacturer, consider:

- Engineering support and willingness to share test reports.

- In-house tooling capability and production mix (stamping, die-cast, CNC).

- QC regime: cycle life, salt spray, and dimensional control.

- Surface treatment capacity (PVD/powder/e-coat) and documented results.

- Lead times, MOQ flexibility, and after-sales support.

Conclusion

Cabinet hinge manufacturing is an interplay of design foresight, material science, precision tooling, and robust testing. For buyers, the cheapest hinge is rarely the most economical over a product’s life; durability, finish integrity, and consistent feel matter. Vet your cabinet hinge manufacturer on engineering transparency, test data, and manufacturing depth. The right factory partnership reduces returns, supports branding, and delivers hardware that keeps cabinets functioning beautifully for years.

About Mingrun

Mingrun is a professional hinge manufacturer that focuses on stable quality, efficient production, and long-term partnerships. We offer wholesale cabinet hinge supply and custom furniture hinge solutions tailored to the needs of global brands, distributors, and OEM/ODM buyers.

Our facility operates with highly automated production lines and strictly follows international cabinet hinge manufacturing standards. Years of experience and consistent customer praise allow us to deliver reliable quality at scale.

Mingrun is the supplier you can trust—flexible in customization, steady in fulfillment, and committed to supporting your business growth.