A properly specified half overlay hinge is an invisible performance component: when it works, nobody notices; when it fails, doors sag, gaps open, and service calls multiply. For cabinet makers and specifiers, hinge selection should be an engineering decision informed by materials, mechanism design, test data, and supplier accountability—not just price or appearance.

In this article, Mingrun, a professional hinge manufacturer, outlines the structural and procurement criteria that define a high-quality half overlay hinge and gives a concise checklist you can use during sourcing and inspection.

Material and Base Construction

Material choice establishes the half overlay hinge’s baseline mechanical performance and corrosion resistance.

- Preferred materials. For long life, choose 304 or 316 stainless steel for coastal or humid environments; solid brass for traditional aesthetics and good corrosion resistance; high-grade cold-rolled steel or die-cast zinc for cost-sensitive lines (inspect for porosity).

- What to watch for. Thin stamped leaves, brittle castings, or hollow pins usually indicate compromised strength. Ask for material certificates (mill test reports) and verify mass/heft—dense parts generally reflect solid construction.

Hinge Arm Geometry and Structural Design

The arm’s shape determines load distribution, overlay control, and fatigue life .

- Crank design. Half-cranked arms position the door correctly relative to the cabinet face; depth and radius of the crank directly affect overlay and interference.

- Reinforcements. Look for ribs, bends, or gussets that reduce bending moments without adding unnecessary bulk.

- Pivot precision. Tight concentricity of pins and minimal play at the joint are indicators of precise manufacture; ball-bearing or roller bearings improve smoothness and longevity in high-cycle applications.

Cup Design and Door Interface

The half overlay hinge cup is the structural interface between door and hinge—its integrity matters.

- Standardization. 35 mm cup diameters are industry common because they balance strength with minimal visual intrusion; deviations are acceptable but must be justified by design needs.

- Cup depth and pull-out resistance. Ensure cup depth matches door thickness; reinforced fixing points or dowels reduce the risk of pull-out on thin doors.

- Fixings. Threaded inserts or larger diameter screws improve holding power compared to thin-sheet screw anchoring.

Motion Control and Opening Characteristics

Smooth, predictable motion reduces wear and improves perceived quality.

- Opening angle. Standard opening angles (e.g., 110° for many half overlay hinge designs) balance access with stress control.

- Damping features. Soft-close dampers and controlled spring mechanisms reduce slamming and extend life; verify damper placement and accessibility for service.

- No dead spots. Test for consistent torque across the motion arc—dead spots indicate poor internal geometry or inadequate lubrication.

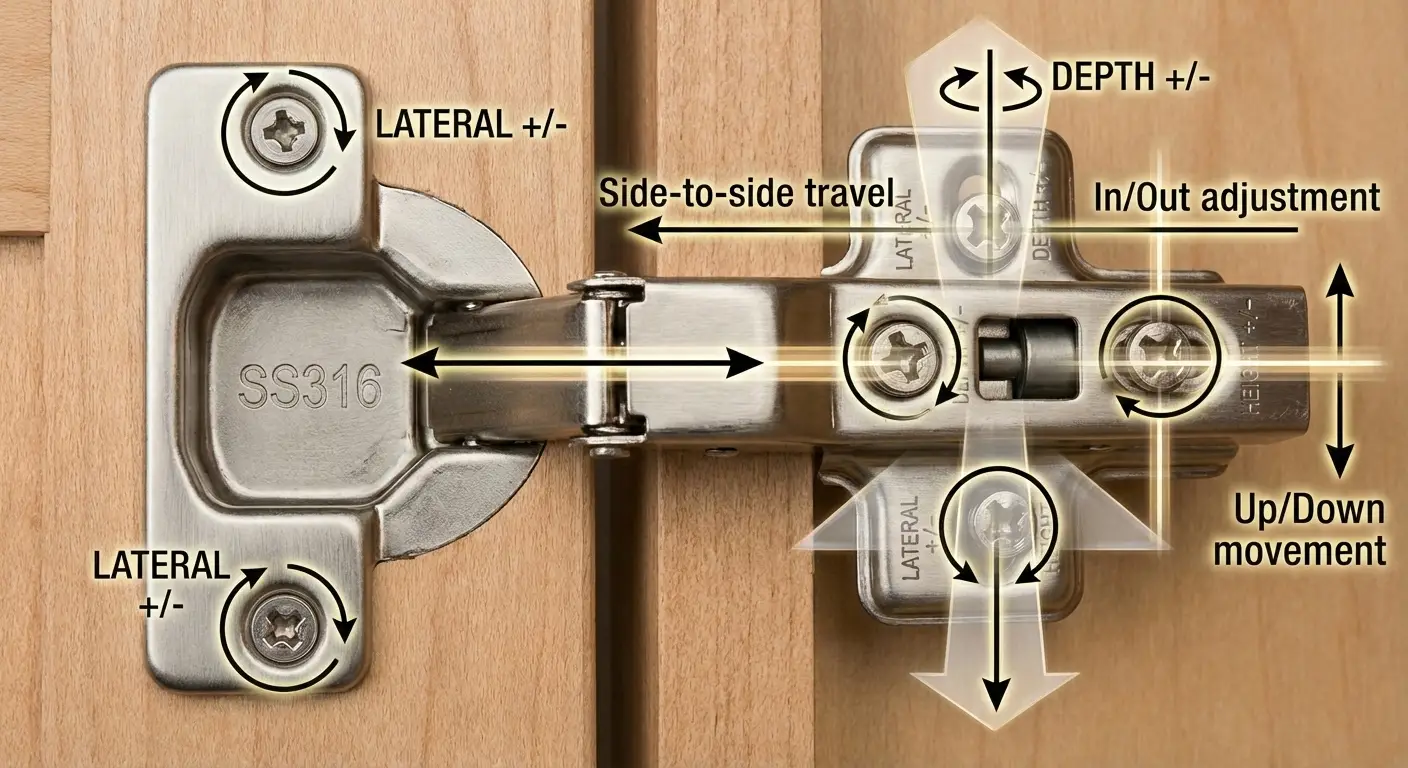

Adjustability and Installation Ease

Field adjustability reduces fitment time and warranty callbacks.

- 3D adjustment. Height, lateral, and depth screws must offer sufficient travel and fine resolution for alignment without resorting to shims.

- Mounting options. Clip-on plates facilitate production speed; screw-on plates can offer higher static load capacity—choose based on installation environment.

- Templates and documentation. Clear drilling templates and torque specifications reduce installer error.

Surface Finish and Corrosion Protection

Finish affects both the appearance and longevity of half overlay hinges.

- Durable finishes. PVD and properly applied passivation on stainless steel deliver the best long-term color stability and corrosion resistance. Electroplating can be acceptable if the plating thickness and pretreatment are documented.

- Salt spray ratings. Request quantified salt spray results (e.g., 48/240/1000 hours) relevant to the end environment. Look for corrosion initiation points in sample inspection.

Durability Testing and Quality Control

Claims are not substitutes for data.

- Cycle life. Expect independent or factory reports for opening/closing cycles—50,000 cycles is a reasonable residential benchmark; 100,000+ for commercial.

- Load tests. Verify sag/deflection under rated door weights and safety margins.

- Batch consistency. Ask how suppliers perform IQC/FQC (incoming and final inspections) and how they handle nonconforming material.

Supplier Credibility and After-Sales

A good part is only as good as its manufacturer and support.

- Documentation. Material certificates, test reports, and installation manuals should be standard.

- Warranty and support. Clear warranty terms, replacement protocols, and response SLAs reduce downstream risk.

- Sample program. Always request production samples and run a short pilot under realistic conditions prior to bulk orders.

Quick Buyer’s Checklist

This can serve as a reference for those who need to buy bulk half overlay hinges from manufacturers:

- Certified material (304/316 SS, solid brass, or verified alloy).

- Correct cup size and depth for door thickness.

- Reinforced arm design with minimal pivot play.

- Documented opening angle and damping performance.

- Full 3D adjustability with adequate range.

- Verified salt spray and cycle-life test reports.

- Finish with quantified corrosion resistance.

- Clear installation templates and torque specifications.

- Available samples and defined warranty terms.

Conclusion

A high-quality half overlay hinge combines appropriate materials, considered mechanical geometry, proven testing, and reliable supplier support. Price is only one dimension; total cost of ownership—measured in reduced callbacks, longer service life, and better end-user experience—often favors slightly higher up-front investment. Use the checklist above when evaluating samples and suppliers: it will help you separate marketing claims from engineering reality and choose hinges that perform in the field.

About Mingrun

Mingrun has been rooted in the furniture hinges industry for decades and is reckoned as a professional hinge manufacturer by our clients all over the world. At Mingrun, we are offering wholesale half overlay hinges, wholesale full overlay hinges, and wholesale inset hinges for our global customers. If your products are going to meet special standards, Mingrun can provide you with our custom half overlay hinge solutions to help you with your projects.

Our custom hinge solution and wholesale hinge supply were delivered:

✅Strong supply chain to ensure competitive price

✅Profession production line

✅Strict hinge quality control to meet any specific standards

✅Tips from expert team members