While most people focus on the engineering or material composition of a hinge, the finish is an equally important factor. Not only does it affect the durability and corrosion resistance of the hinge, it also determines how well the hinge blends in or stands out in the overall design.

As a professional furniture hinge manufacturer, we will discuss with you the surface treatment technologies commonly used in hinge production, their technical advantages and how they bridge the gap between functionality and aesthetics.

Why Surface Finishing Matters

Surface finishing is more than just a final touch. It directly impacts:

- Corrosion resistance

- Scratch and wear protection

- Ease of maintenance

- Visual harmony with furniture or cabinetry

- Tactile quality and texture

For manufacturers, offering the right finishing technique can make or break a product’s market appeal, especially in premium furniture or architectural applications.

Common Surface Finishing Techniques for Hinges

Electroplating

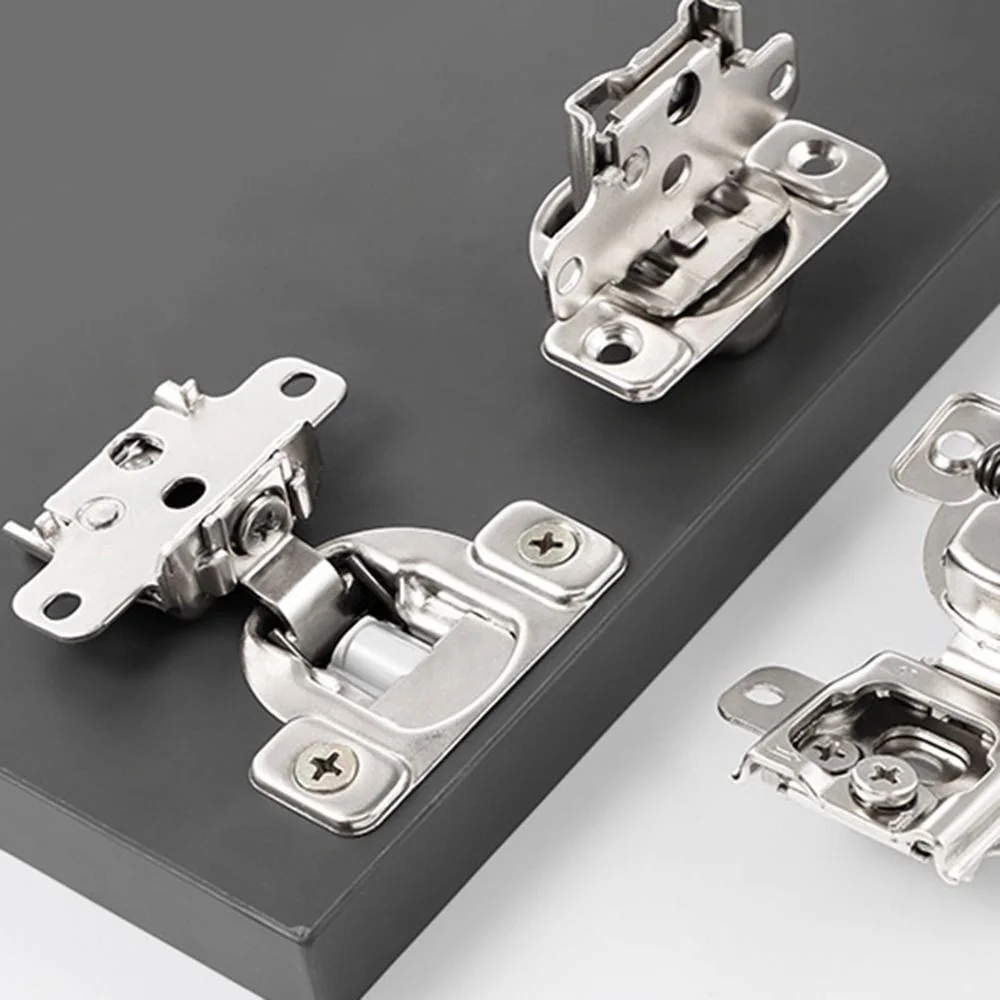

One of the most widely used surface treatment methods is electroplating, which uses an electric current to coat the hinge surface with a thin layer of metal, such as zinc, nickel or chromium. This creates a smooth, bright and corrosion-resistant surface.

- Applications: Chrome hinges are commonly found in bathrooms and kitchens because of their resistance to moisture.

- Aesthetics: Provides a shiny, modern, sophisticated look.

Powder Coating

Powder coating is a process where a dry powder (usually polyester or epoxy) is electrostatically applied to the hinge and cured under heat. This technique results in a durable, uniform and environmentally friendly coating.

- Applications: Commonly used in industrial or commercial grade hinges.

- Aesthetics: Available in a variety of colors and textures, including matte, satin, and textured finishes.

Anodizing (for Aluminum Hinges)

Anodizing is an electrochemical process that thickens the natural oxide layer on aluminum hinges. This can enhance the corrosion resistance of aluminum hinges and dye the surface in a variety of colors.

- Applications: Lightweight decorative hinges used in office furniture, aluminum cabinets or lightweight partitions.

- Aesthetics: Available in elegant color finishes like bronze, black, champagne and silver.

Polishing / Mirror Finish

Mirror polishing is a common precision surface treatment method used in industrial manufacturing. The process involves multiple stages of fine grinding and polishing, using specialized abrasives and polishing agents, to achieve a highly reflective mirror surface.

- Applications: Produces a smooth, burr-free surface, enhances corrosion resistance, simplifies cleaning, and is used for decorative hinges.

- Aesthetic impact: High-gloss, elegant, and premium feel.

Black Oxide Coating

Black oxide is a chemical conversion coating for ferrous materials, giving the hinge a dark, matte appearance with mild corrosion resistance when oiled.

- Applications: Industrial or rustic style furniture.

- Aesthetic Impact: Rugged, vintage charm.

Choosing the Right Finish: Factors to Consider

Whether you are a manufacturer, designer or supplier, choosing the right surface finish should depend on:

- End-use environment: Moisture, heat, and abrasion factors.

- Design intent: Modern, industrial, vintage, or luxury styles.

- Budget and production volume: Certain finishes are more cost-effective for mass production.

- Material compatibility: Not all finishes are suitable for every base metal.

Conclusion

In today’s competitive market, it’s no longer enough for hinges to just work; they must also look good and last. A carefully selected finish not only extends the life and strength of the hinge, but also enhances the overall aesthetic of the furniture or building.

Looking for High-Quality Hinges in Bulk?

As a professional hinge manufacturer, Mingrun specializes in producing wholesale furniture hinges, including soft close hinges and regular hinges. With advanced surface treatment capabilities and strict quality control, we ensure that every hinge we produce combines functionality, durability, and aesthetics.

Contact us today to explore how we can help you create the perfect hinge solution for your project.