Cabinet hinges can be classified by their installation method, and there are inset hinges and overlay hinges in this category. Selecting the right one strongly affects a cabinet’s look, function, and long-term performance.

Understanding their mechanics, design implications, and trade-offs will reduce troubles for DIYers and designers. In the blog, Mingrun, a professional hinge manufacturer, will explain the difference, the common hinge types, installation and maintenance considerations, and how to decide which is best for your project.

Quick Definitions: Inset vs Overlay

- Inset hinge: the door sits inside the cabinet frame and is flush with the face of the frame when closed. The hinge must allow the door to clear the inside of the frame as it opens.

- Overlay hinge: the door covers part (half overlay) or nearly all (full overlay) of the cabinet face frame. Overlay doors overlap the cabinet edge when closed.

Both join the door to the cabinet, but they produce very different visual and technical outcomes. Knowing the hinge types within these families is the first step toward a successful selection.

Differences in Structure and Operation

Inset doors have strict tolerances: the door has to fit within a reveal with minimal gaps, so careful considerations must be given to hinge mounts and cup depths. Inset hinges typically have a shorter arm or are constructed with specialized geometry to allow the door to swing open without rubbing against the frame.

Overlay hinges, on the other hand, typically use a longer short arm and different mounting plates to determine how much of the door overlays the frame. A full overlay hinge can provide the most visible panel and is commonly used on frameless (Euro) cabinets. A half-overlay hinge allows for two doors to share one center stile on framed cabinets.

Most modern hinges offer 3-way adjustment (up/down, left/right, in/out), but the range and adjustment vary by hinge type.

Where Each Type Works Best

- Inset: ideal for high-end custom cabinetry, period furniture, and any design where a flush, classical look is desired. It suits solid wood and high-precision joinery.

- Full overlay: best for modern, minimalist kitchens where smooth, uninterrupted surfaces are preferred. It maximizes accessible opening space.

- Half overlay: a practical choice for framed cabinets where budget or multi-door designs matter.

- Concealed hinges: preferred where a clean exterior is the priority, common in contemporary and frameless cabinet systems.

Installation and Craftsmanship Differences

- Inset: requires accurate door thickness, perfectly cut reveal, and precise hinge cup placement (typically using a 35mm cup on many European hinges). Small measurement errors cause rubbing or uneven gaps. Professional installation is recommended.

- Overlay: generally more forgiving. Frameless systems with clip-on plates allow faster assembly on production lines and easier door removal for shipping or service.

Tools and jigs: Use a hinge jig for cup drilling, a good level, clamps, and measure twice before drilling. For inset work, tighter torque control and trial-fitting are crucial.

Adjustment and Maintenance

All modern hinge types offer adjustment screws. Best practice: adjust one axis at a time and check the door after each tweak. Common problems and fixes:

- Uneven gaps: adjust lateral screw (left/right).

- Door sagging: tighten mounting screws and check for stripped holes — repair with wood filler/dowel if needed.

- Rubbing on frame: adjust depth (in/out) or reset cup position.

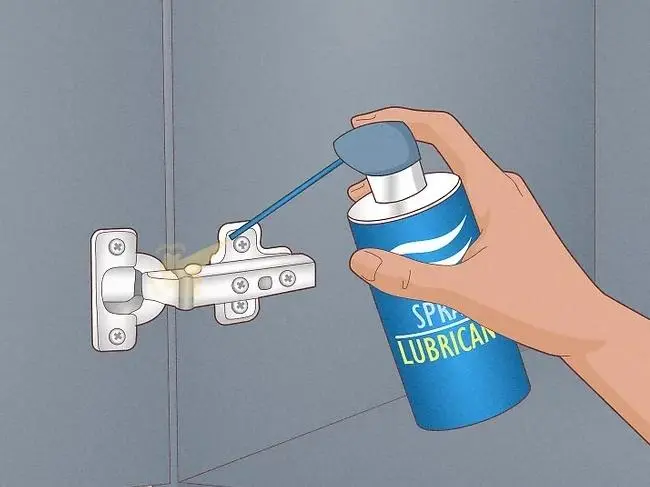

Maintenance routine: clean debris, lubricate pivot points with silicone or PTFE lubricant, and check screw torque annually.

Strength, Durability, and Load Considerations

Inset installations often place different mechanical loads on the frame and hinges—heavy, solid-wood inset doors may require reinforced or double hinge points. Overlay installations are generally more structurally forgiving regarding load distribution, as the door weight is typically supported across the cabinet side panel. For large or heavy doors (glass or full-height wooden panels), choose heavy-duty variants or multiple hinge points. Material matters too: stainless steel and brass alloys resist corrosion better in humid environments.

Cost and Supply-chain Implications

- Inset hinges tend to increase labor and fitting costs due to precision needs. They are more common in small-batch, custom work.

- Overlay hinges, especially clip-on European styles, are lower cost to install in high volumes and suit factory production.

Availability: Full overlay concealed hinges are commodity items with broad supply; specialized inset hinges or finishes may have longer lead times or higher MOQs.

Quick Selection Guide (Decision Checklist)

- Want a modern, continuous look → choose full overlay or concealed overlay.

- Need a classic, flush finish → choose inset.

- Working with framed cabinets and multiple doors on one stile → choose half overlay.

- Prioritize fast install and serviceability → prefer clip-on overlay hinges.

- Heavy doors or humid environment → select heavy-duty or stainless hinge variants.

Conclusion

Selecting between inset and overlay is both an aesthetic and technical decision. The right hinge types will depend on cabinet style, manufacturing method, budget, and how much precision you’re willing to commit to during installation. Measure carefully, test samples, and match hinge selection to the desired look and daily use case—doing so will ensure doors operate smoothly and look right for years to come.

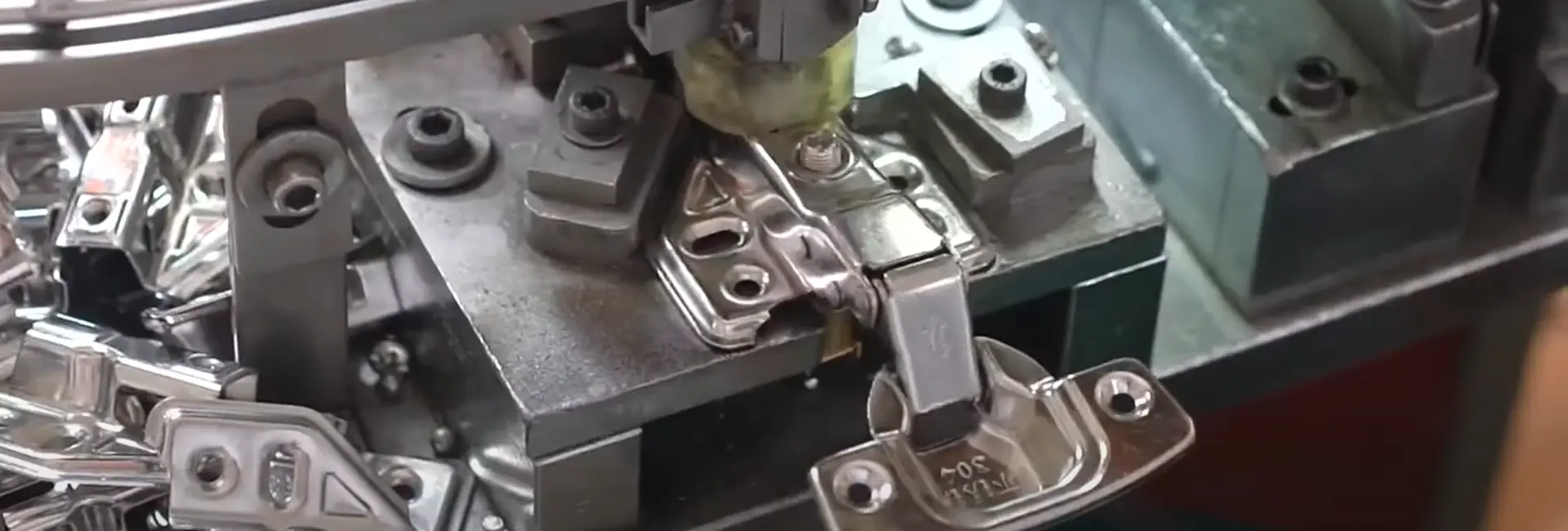

About Mingrun

At Mingrun, precision meets reliability. As a professional hinge manufacturer, we specialize in wholesaling hinges for cabinets and furniture. With our own factory and advanced production lines, we deliver high-volume orders with consistent quality in our custom hinge solutions. Every product undergoes a rigorous QA process that meets international standards, ensuring durability and smooth performance for every installation.

FAQ

Q: Is an inset hinge always better quality than an overlay hinge?

A: No. Quality depends on hinge design, material, and installation — a high-quality overlay hinge can outperform a cheap inset hinge.

Q: What test data should I request from suppliers?

A: Ask for salt spray hours, cycle life (open/close cycles), three-way adjustment range, and material/batch certificates, Certificate of Compliance(CoC).

Q: How should I estimate installation cost and lead time?

A: Include installation time, sample trial-fit, MOQ effects, and finish processing time; using clip-on hinges can cut installation labor significantly.

Q: Should I choose inset or overlay hinges?

A: Choose an inset for a classic, flush look; full overlay (concealed) for a modern seamless look; half overlay if you need two doors sharing a stile or want a budget option.

Q: What simple maintenance do hinges need?

A: Wipe clean, check and tighten screws periodically, and lubricate pivot points with silicon or PTFE spray when noisy.